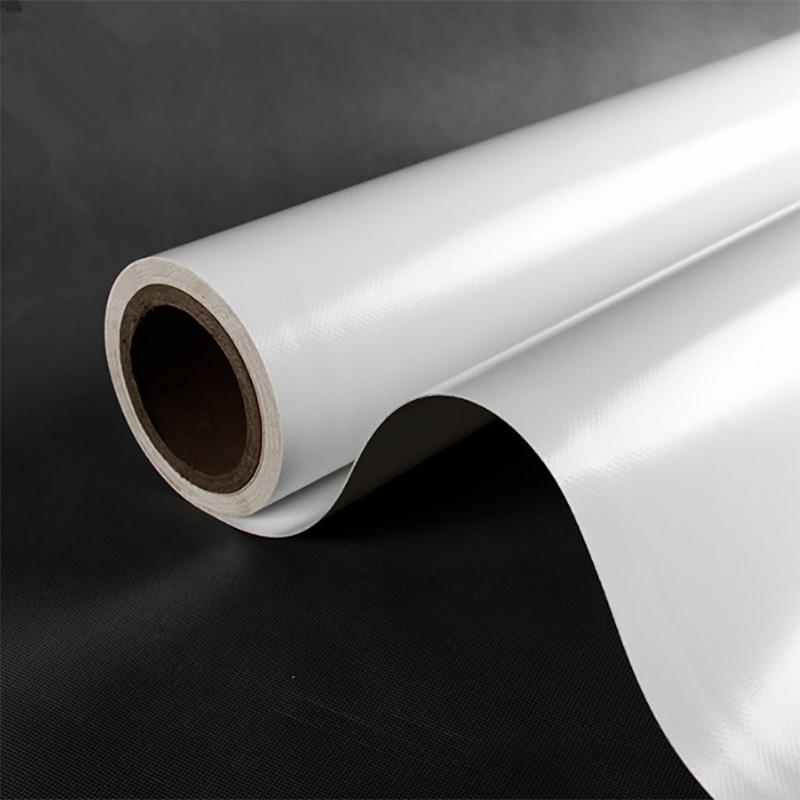

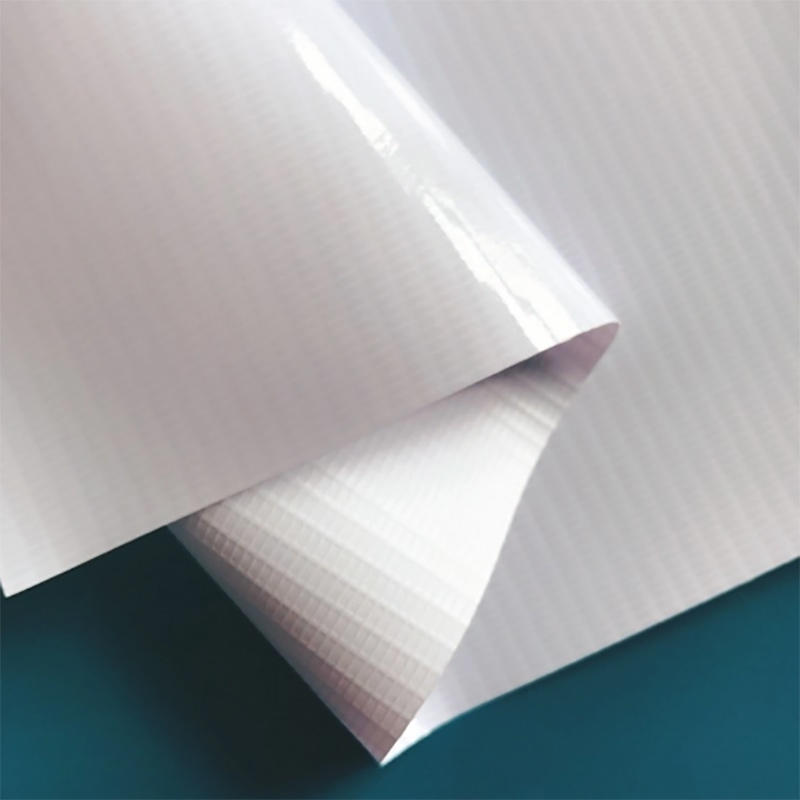

PVC Flex Banner Manufacturers

Basic Info.:

|

Gram Weight |

220/380/400/550/680/1000gsm |

|

Material |

100% Polyester yarn with PVC Coating |

|

Structure |

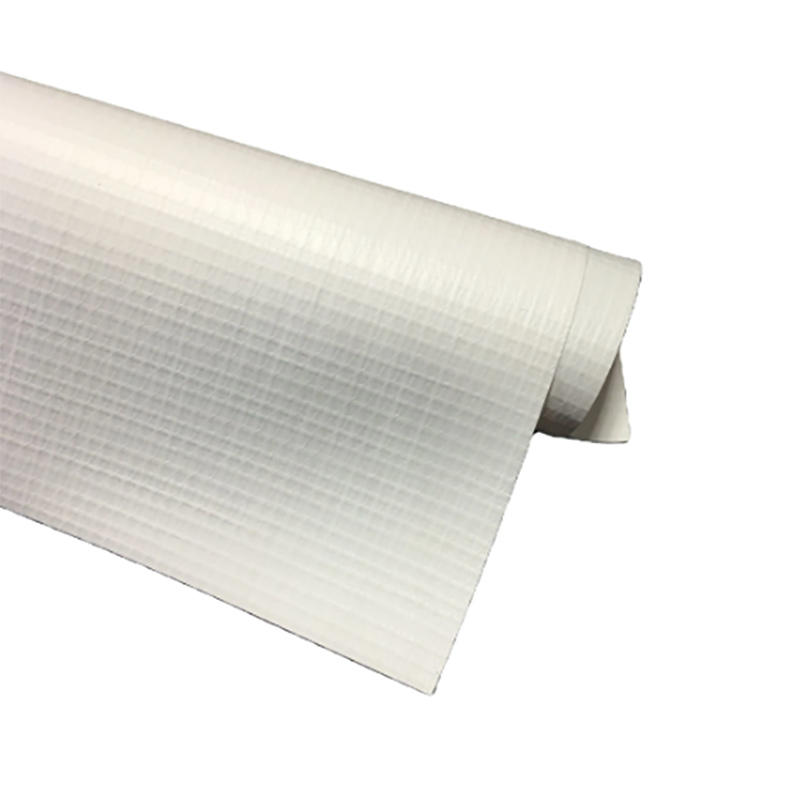

PVC Coated Polyester Fabric |

|

Width |

1.5-3.2m |

|

Length |

50m |

|

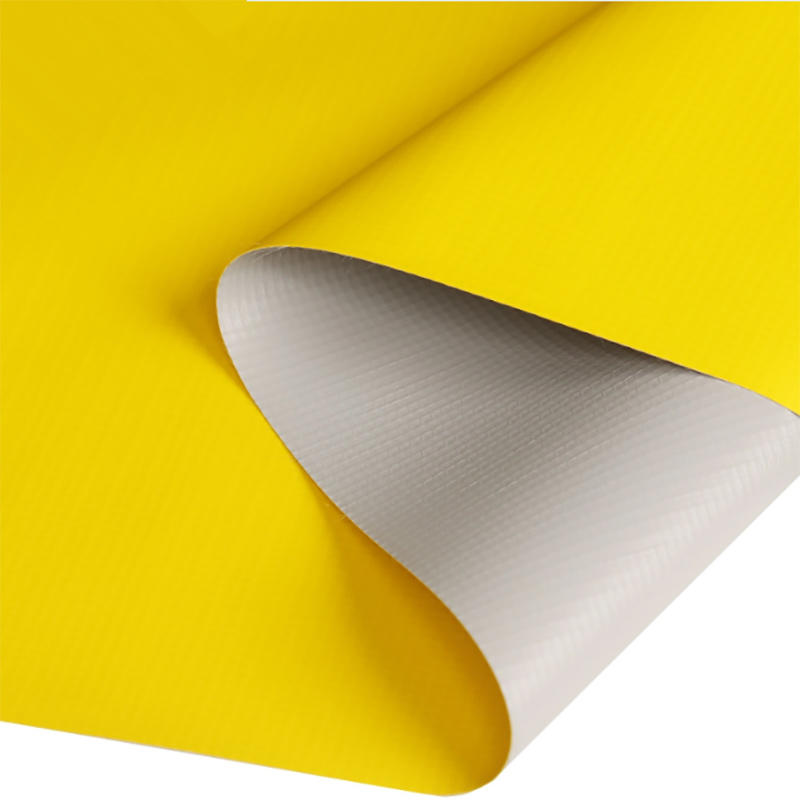

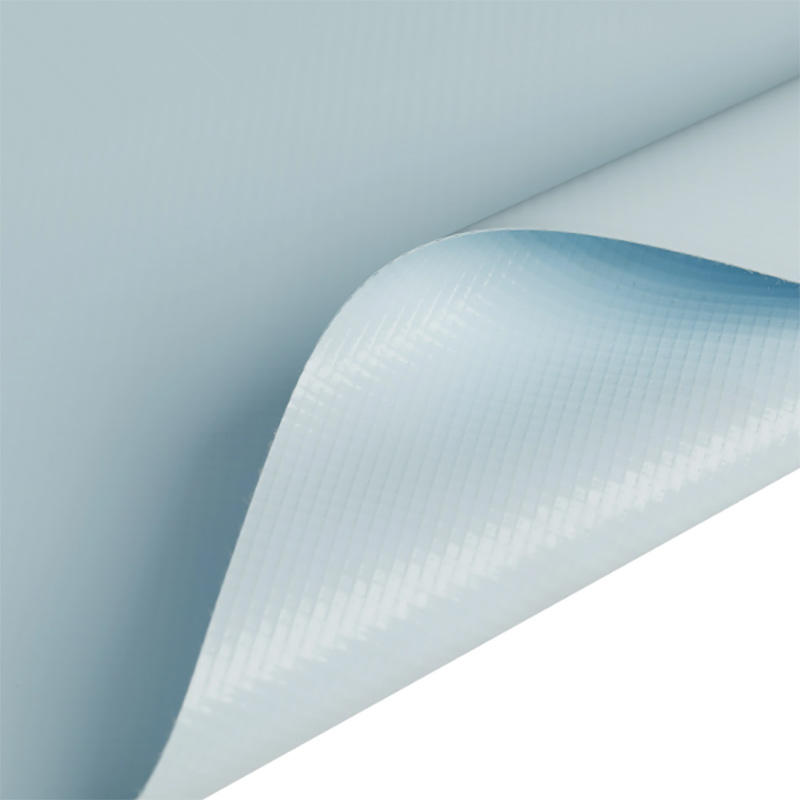

Color |

Customized |

|

Surface |

Glossy, Semi Glossy, Matte, Semi Matte |

|

MOQ |

>2500m |

|

Density |

9*9 12*12 18*12 28*28 36*36 |

|

Yarn |

200d*300d 300d*500d 500d*500d 1000d*1000d |

|

Flame Retardant |

M1; M2; B1 |

|

Special requirement |

Anti-UV, Anti-Mildew, Anti-Static, Anti-Scratch |

|

Sample |

A4 Size Sample Free |

|

Lead Time |

20-35 Working Days |

Application:

Products are widely used in weddings, banquets, commodity exhibitions, leisure travel, outdoor tourism, outdoor exercises, medical outdoor first aid and fire protection. The products have high-strength wear resistance, excellent tensile resistance, tear resistance and peeling resistance. It also has the characteristics of fire retardant, anti-ultraviolet and anti-oxidation, anti-mildew and anti-bacterial, waterproof and stain-resistant, high-temperature resistance and cold resistance.

Product Features:

1. Laminated technology & Hot-melt Coating & Knife coating technology

2. Outstanding tearing strength for welding

3. Flame retardant character (optional), M1; M2; B1

4. Temperature resistance: -30-70℃

5. Cold Crack Resistance, Anti-Mildew, Anti-Static treatment, Waterproof

6. Anti ultraviolet treatment(UV).(optional)

7. Acrylic treatment (optional)

Application:

Information to be updated

Zhejiang Xinria Textile Material Co., Ltd.

Company Profile

Zhejiang Xinria Textile Material Co., Ltd. is professional China PVC Flex Banner manufacturers and Wholesale PVC Flex Banner factory. It is a high-tech enterprise specializing in the production of PVC coated fabrics, PVC mesh fabrics, TPU mesh fabrics, mesh fabrics, and architectural membranes. The company is located in Haining Qianjiang Industrial Park. Since its establishment, it has been committed to the research, development, production and sales of high-quality architectural membranes and coated fabrics.

Our company's PVC Flex Banner have been widely used in large public facilities: park landscape architecture, parking sheds, inflatable membrane structures, large stadiums, airport facilities and other architectural fields. Advanced technology in the field of European membrane materials, the products sell well in domestic and foreign markets, and have won unanimous praise from customers.

The company has always been adhering to the business philosophy of excellence and continuous innovation, relying on advanced equipment and technology, and forward-looking scientific research spirit to PVC Flex Banner high-quality products. Cooperate with new and old customers to win-win and create a better future.

News

Understand the latest market dynamics and industry trends

-

What is the tensile strength of the PVC Coated Polyester Fabric? How does it perform under tension or stress?

PVC coated polyester fabric is a popular material used for producing flex banner...--16 May

-

How long does the PVC coating last? What conditions can it withstand?

PVC coated polyester fabric is a popular material used for producing flex banner...--16 May

-

PVC transparent film: unlimited innovation in the field of construction and decoration

PVC coated polyester fabric is a popular material used for producing flex banner...--16 May

-

PVC transparent film: the leader in flexibility

PVC coated polyester fabric is a popular material used for producing flex banner...--16 May

简体中文

简体中文 English

English