When choosing PVC-coated polyester mesh fabric, there are several factors to consider to ensure you select the most suitable material for your specific application. Here are some key factors to keep in mind:

Purpose and Application: Determine the intended purpose of the fabric and the specific application it will be used for. PVC coated polyester mesh fabrics have a wide range of applications, including outdoor furniture, awnings, banners, screens, safety barriers, and more. Understanding the intended use will help you choose the right fabric with the appropriate characteristics.

Material Quality and Durability: Evaluate the quality and durability of the PVC-coated polyester mesh fabric. Look for a high-quality polyester base fabric that is resistant to UV radiation, tearing, abrasion, and chemical exposure. Ensure that the PVC coating is of good quality, providing excellent weather resistance and longevity.

Mesh Size and Openness: Consider the desired level of openness and airflow. PVC-coated polyester mesh fabrics come in various mesh sizes, which determine the size of the openings in the fabric. A larger mesh size will allow more airflow but may sacrifice some privacy or blockage of sunlight. Smaller mesh sizes offer more privacy but may reduce airflow.

Weight and Thickness: Consider the weight and thickness of the fabric. The weight and thickness will influence the overall strength, durability, and flexibility of the material. The specific application and the level of durability required will determine the appropriate weight and thickness.

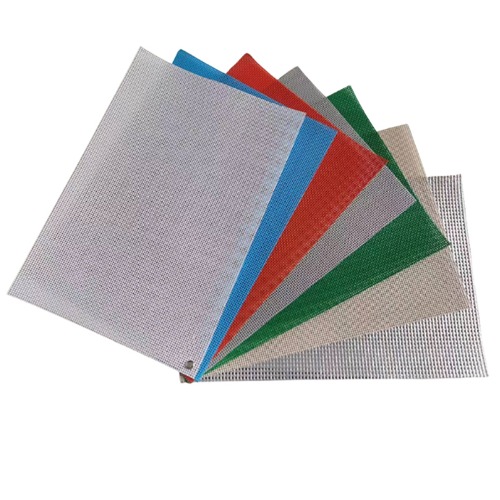

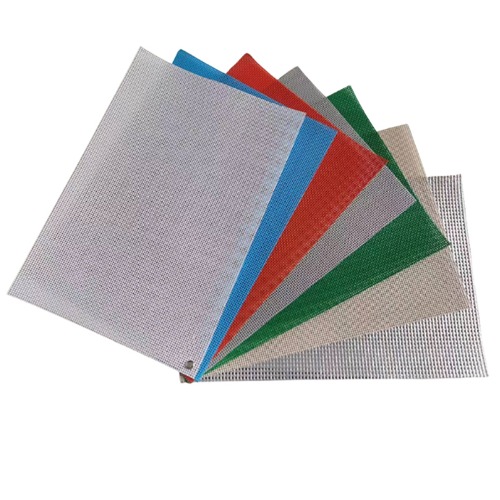

Color and Aesthetic Appeal: Choose a color that matches your aesthetic preferences or complements the surrounding environment. PVC-coated polyester mesh fabrics come in a variety of colors, allowing you to find one that aligns with your design vision or branding requirements.

Flame Retardancy: If fire safety is a concern, look for PVC-coated polyester mesh fabrics that are flame retardant and comply with relevant fire safety standards. This is particularly important in applications where fire resistance is required, such as in public spaces or commercial settings.

Maintenance and Cleanability: Consider the maintenance requirements and cleanability of the fabric. PVC-coated polyester mesh fabrics are typically easy to clean and maintain. Look for fabrics that are resistant to stains, mold, and mildew, and can be easily cleaned with mild soap and water.

Supplier Reputation: Choose a reputable supplier or manufacturer that offers high-quality PVC-coated polyester mesh fabrics. Consider their experience, customer reviews, and certifications to ensure you are purchasing from a reliable source.

Meanwhile, the production of PVC-coated polyester mesh fabric involves several steps to achieve the desired characteristics and quality. While the specific production process may vary depending on the manufacturer and equipment used, here is a general overview of the production steps:

Polyester Fabric Preparation: The process begins with the preparation of the polyester fabric. The polyester fibers are spun into yarns, which are then woven or knitted to create the base fabric. The fabric is typically produced in rolls of varying widths and lengths.

Coating Preparation: The PVC (Polyvinyl Chloride) coating formulation is prepared. PVC is a thermoplastic polymer that provides durability, weather resistance, and other desirable properties to the fabric. The PVC coating formulation may include additives such as plasticizers, stabilizers, and pigments to enhance specific characteristics and color.

Coating Application: The PVC coating is applied to the polyester fabric using various coating techniques. The most common methods include dip coating or knife coating. In dip coating, the fabric is immersed into a bath of the PVC coating formulation, and excess coating is squeezed off. In knife coating, a knife or blade spreads the PVC coating evenly onto the fabric.

Curing and Drying: After the coating is applied, the fabric is subjected to a curing process to bond the PVC coating to the polyester fabric. This is typically done by passing the fabric through a heated oven or using infrared radiation. The curing process ensures the PVC coating becomes a solid and forms a strong bond with the fabric.

Inspection and Quality Control: Once the curing process is complete, the coated fabric undergoes inspection and quality control measures. This includes visual inspection to check for any coating defects, such as uneven thickness, bubbles, or imperfections. Other quality control tests may include checking for color accuracy, tensile strength, tear resistance, and other performance parameters.

Finishing: After passing quality control, the PVC-coated polyester mesh fabric may undergo additional finishing processes to enhance its properties. This may include processes such as calendaring (passing the fabric through heated rollers to improve smoothness and texture), embossing (creating patterns or textures on the surface), or flame retardant treatment (if required for specific applications).

Cutting and Packaging: The final step involves cutting the PVC-coated polyester mesh fabric into the desired sizes or lengths. The fabric is then packaged in rolls or folded into manageable units, ready for storage, shipment, or further processing.

English

English عربى

عربى