In modern industries, materials that combine durability, functionality, and aesthetic appeal are in high demand. Among these, PVC-coated mesh fabric stands out as one of the most adaptable and reliable materials used across sectors such as architecture, transportation, agriculture, and advertising. But what makes this fabric so special, and why has it become the preferred choice for so many diverse applications?

What Is PVC-Coated Mesh Fabric?

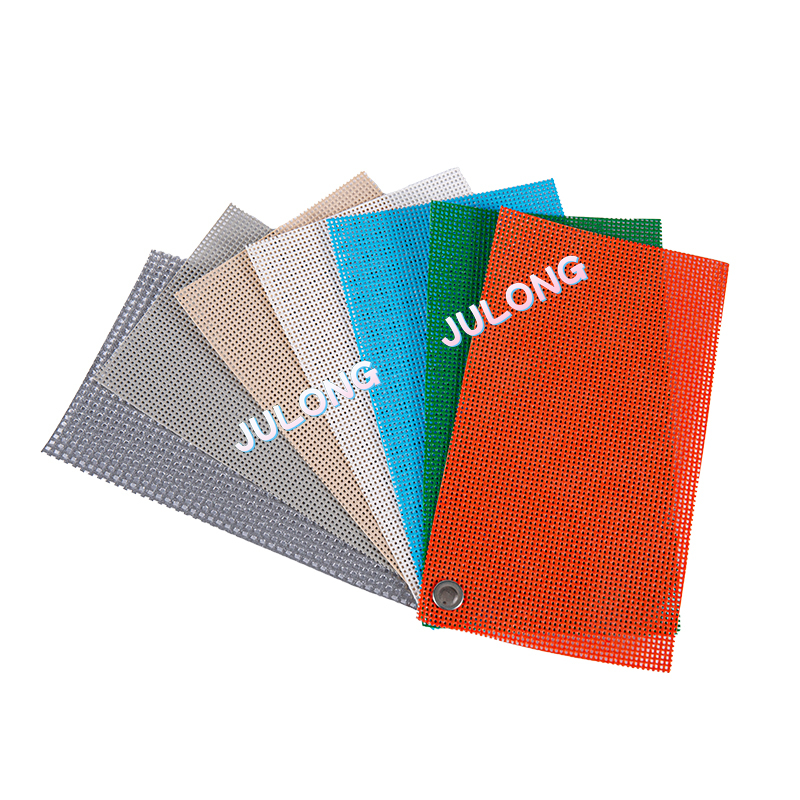

PVC-coated mesh fabric is a synthetic textile made by coating a woven polyester or fiberglass base fabric with polyvinyl chloride (PVC). This coating gives the mesh a durable, waterproof, and UV-resistant surface while maintaining its flexibility and lightweight structure. The “mesh” design means the fabric contains tiny, evenly spaced holes that allow air and light to pass through while still providing excellent strength and weather resistance.

The result is a material that is strong, breathable, and resistant to tearing, corrosion, and fading, making it ideal for outdoor and industrial uses.

How Is PVC-Coated Mesh Fabric Made?

The production process of PVC-coated mesh fabric involves several precise steps to ensure consistency and quality:

- Base Fabric Weaving: The foundation of the material is usually a polyester or fiberglass mesh, woven into a grid pattern to provide structural strength.

- Coating Process: The base mesh is coated with liquid PVC, which can be done through knife coating, lamination, or calendaring. The coating ensures a uniform surface that bonds tightly with the fibers.

- Heat Treatment: The coated fabric is then heated to fuse the PVC with the mesh, enhancing durability and flexibility.

- Finishing: The material can be treated for UV resistance, anti-mildew protection, flame retardancy, or color customization.

This meticulous process results in a versatile fabric that performs well in harsh conditions while maintaining its form and appearance for years.

What Are the Key Properties of PVC-Coated Mesh Fabric?

The popularity of PVC-coated mesh fabric stems from its exceptional physical and chemical properties. Some of its defining characteristics include:

- High Tensile Strength: The polyester base ensures the fabric can withstand high stress without tearing or deformation.

- Weather Resistance: PVC coating makes the material waterproof, UV-resistant, and resistant to extreme temperatures, ensuring longevity even in outdoor environments.

- Breathability: The mesh structure allows air to circulate, preventing heat buildup and condensation.

- Lightweight and Flexible: Despite its strength, the material remains easy to handle, install, and transport.

- Chemical Resistance: It resists oil, grease, salt, and most acids, making it suitable for industrial and marine applications.

- Easy Maintenance: The smooth PVC surface is easy to clean and resists mold and mildew growth.

These properties make PVC-coated mesh fabric a practical and cost-effective solution for both temporary and permanent structures.

Where Is PVC-Coated Mesh Fabric Commonly Used?

Because of its outstanding versatility, PVC-coated mesh fabric is widely used in numerous industries. Let’s explore some of its key applications:

1. Architectural and Construction Uses

PVC-coated mesh fabric plays a vital role in modern architectural designs. It’s often used for:

- Building facades and shading systems: The mesh allows natural light and airflow while reducing solar heat gain, helping improve energy efficiency.

- Tensile structures and awnings: Its flexibility makes it perfect for creating visually striking roofs and canopies.

- Scaffolding covers and safety nets: It prevents debris from falling while allowing ventilation at construction sites.

Its combination of aesthetics and functionality helps architects design sustainable, lightweight, and innovative structures.

2. Advertising and Digital Printing

PVC-coated mesh fabric is one of the most popular materials for billboards, banners, and stage backdrops. The perforated surface allows wind to pass through, reducing pressure and preventing tearing — a critical feature for large outdoor displays. Additionally, its smooth coating ensures vibrant, long-lasting print quality, making it ideal for high-impact graphics.

3. Agriculture and Greenhouses

In agricultural environments, PVC-coated mesh fabric is used for shade nets, greenhouse coverings, and livestock enclosures. The breathable material allows air circulation while protecting crops or animals from harsh sunlight, wind, and rain. Its anti-fungal and anti-UV properties ensure long-term use without degradation.

4. Transportation and Logistics

Heavy-duty PVC-coated mesh fabrics are used for truck tarpaulins, trailer covers, and cargo containment systems. The material offers superior tear resistance and waterproofing, protecting goods during transport in all weather conditions. Its flexibility also makes it easy to handle, fold, and secure.

5. Marine and Outdoor Applications

PVC-coated mesh fabric is often found in boat covers, sunshades, and outdoor furniture. Its resistance to saltwater corrosion and UV damage ensures reliability in marine environments. For outdoor furniture, the mesh structure offers comfort, durability, and easy cleaning.

6. Sports and Recreation

Sports facilities use PVC-coated mesh fabric for stadium roofing, fences, safety nets, and sports banners. The fabric’s strength and flexibility make it suitable for high-stress environments, while its color variety allows customization for branding and aesthetics.

What Are the Advantages of Using PVC-Coated Mesh Fabric?

PVC-coated mesh fabric offers several distinct advantages over traditional fabrics and materials:

- Exceptional Durability: The PVC coating enhances the mesh’s ability to resist wear and tear, extending its lifespan significantly.

- Customizability: Available in different weights, thicknesses, colors, and coatings, it can be tailored to specific industrial needs.

- Cost-Effectiveness: Long-lasting performance means fewer replacements and reduced maintenance costs.

- Eco-Friendly Options: Many manufacturers now offer recyclable and low-VOC (volatile organic compound) PVC coatings.

- Enhanced Aesthetic Appeal: It can be printed or colored for branding, design, or artistic purposes without compromising function.

How Does PVC-Coated Mesh Fabric Compare with Other Materials?

When compared to other industrial fabrics such as nylon, canvas, or polyethylene tarpaulin, PVC-coated mesh fabric stands out for its balance of strength, flexibility, and weather resistance.

- Versus Canvas: While canvas offers a natural appearance, it absorbs water and deteriorates faster outdoors. PVC mesh, on the other hand, is waterproof and long-lasting.

- Versus Nylon or Polyester Tarps: Standard tarps lack breathability and can trap heat or moisture. The mesh structure of PVC-coated fabric prevents these issues.

- Versus Metal Screens: Metal offers rigidity but is heavy, prone to corrosion, and difficult to install. PVC-coated mesh provides similar airflow benefits with much lighter weight and easier handling.

In short, PVC-coated mesh fabric offers an unbeatable combination of practicality, durability, and design flexibility.

How to Maintain and Care for PVC-Coated Mesh Fabric?

One of the main benefits of PVC-coated mesh fabric is its low maintenance requirements. To ensure longevity, follow these guidelines:

- Regular Cleaning: Wipe down surfaces with mild soap and water to remove dust and dirt. Avoid abrasive cleaning tools that might scratch the coating.

- Avoid Harsh Chemicals: Strong acids, solvents, or chlorine-based cleaners can damage the PVC layer.

- Proper Storage: When not in use, roll or fold the fabric loosely and store it in a cool, dry area away from direct sunlight.

- Periodic Inspection: Check for cuts, frayed edges, or areas where the coating may be peeling. Prompt repair can prevent further damage.

With minimal care, high-quality PVC-coated mesh fabrics can last for years, even in harsh environments.

Are There Eco-Friendly Innovations in PVC-Coated Mesh Fabric?

As sustainability becomes a key focus globally, the PVC-coated fabric industry is also evolving. Modern innovations include:

- Phthalate-Free PVC Coatings: These reduce the environmental impact and improve health safety.

- Recyclable Mesh Fabrics: Some products are now designed for easier recycling at the end of their life cycle.

- Energy-Efficient Manufacturing: Advanced coating processes consume less energy and produce fewer emissions.

These developments make PVC-coated mesh an increasingly sustainable option for eco-conscious projects.

Why Is PVC-Coated Mesh Fabric the Future of Functional Textiles?

From architectural shading to heavy-duty transportation covers, PVC-coated mesh fabric proves that a single material can serve multiple industries effectively. Its combination of strength, durability, flexibility, and customizability makes it one of the most practical materials available today.

As technology continues to advance, manufacturers are developing smarter coatings, improved UV resistance, and eco-friendly formulations, ensuring that PVC-coated mesh fabric will remain a cornerstone material for modern design, construction, and industrial use.

Conclusion: A Material That Balances Performance and Aesthetics

PVC-coated mesh fabric has revolutionized how industries approach material design. Whether for buildings, advertising, transportation, or agriculture, it offers unmatched advantages in longevity, performance, and cost efficiency. The ability to merge strength with flexibility—and function with form—makes it one of the most valuable technical textiles available today.

As industries continue to demand more sustainable, lightweight, and adaptable materials, PVC-coated mesh fabric will continue to play a crucial role in shaping the future of functional and architectural design.

English

English عربى

عربى