PVC-coated mesh fabric is a composite material made by coating a woven or knitted base mesh—typically polyester—with a layer of polyvinyl chloride (PVC). This combination creates a fabric that balances strength, flexibility, and resistance to environmental factors. The open mesh structure allows airflow and visibility, while the PVC coating enhances durability, weather resistance, and ease of maintenance.

Because of these characteristics, PVC-coated mesh fabric is widely used in outdoor shading systems, fencing, tarpaulins, safety barriers, industrial covers, and architectural applications. Selecting the right specification is essential, as performance can vary significantly depending on yarn strength, coating thickness, and finishing treatments.

Defining Your Application Requirements First

Before comparing technical specifications, it is important to clearly define how and where the PVC-coated mesh fabric will be used. Outdoor and industrial projects often impose different stresses on the material, and understanding these conditions helps narrow down suitable options.

Key factors include whether the fabric will be permanently installed or temporarily deployed, the level of mechanical stress it will experience, and the surrounding environmental conditions. For example, a sunshade canopy has very different requirements from an industrial safety screen near heavy machinery.

Mesh Base Material and Yarn Strength

The performance of PVC-coated mesh fabric starts with the base mesh. Most high-quality products use polyester yarn due to its excellent tensile strength, dimensional stability, and resistance to stretching. The denier or yarn count directly affects how much load the fabric can withstand.

For industrial applications such as scaffolding covers or safety fencing, higher yarn strength is critical to prevent tearing under tension. For decorative or shading purposes, a lighter mesh may be sufficient and more cost-effective.

Weave Density and Mesh Opening

Mesh density determines airflow, light transmission, and visibility. A tighter weave offers better privacy and wind resistance, while a more open mesh improves ventilation and reduces wind load. Choosing the right balance depends on whether airflow or coverage is the priority in your project.

PVC Coating Thickness and Quality

The PVC coating is responsible for protecting the base mesh and extending the fabric’s service life. Coating thickness directly influences durability, abrasion resistance, and resistance to environmental exposure.

For outdoor use, a thicker and evenly applied PVC coating helps prevent cracking, peeling, and moisture penetration. In industrial environments, high-quality coatings also protect against oils, chemicals, and frequent cleaning.

Surface Finish Options

PVC-coated mesh fabric may feature matte, glossy, or textured finishes. Matte finishes reduce glare for outdoor shading, while glossy surfaces are easier to clean in industrial settings. Some fabrics also include anti-slip or embossed finishes for specialized uses.

Weather Resistance for Outdoor Projects

Outdoor applications expose PVC-coated mesh fabric to sunlight, rain, wind, and temperature changes. UV resistance is one of the most critical performance factors, as prolonged sun exposure can degrade both the PVC coating and the underlying yarn.

High-quality fabrics include UV stabilizers in the PVC formulation to slow aging and color fading. For projects in coastal or high-humidity environments, resistance to mold and mildew is also important to maintain appearance and structural integrity.

Mechanical Strength and Load Performance

Industrial projects often require PVC-coated mesh fabric to withstand tension, impact, and repeated handling. Tensile strength, tear resistance, and edge stability should be carefully evaluated.

Reinforced edges, welded seams, or additional hemming can significantly improve load performance, especially for large panels or installations exposed to strong winds.

| Performance Aspect | Outdoor Use | Industrial Use |

| UV Resistance | Very important | Moderately important |

| Tear Strength | Medium | High |

| Chemical Resistance | Low to medium | High |

Fire Retardancy and Safety Standards

For many industrial and public outdoor installations, fire performance is a mandatory consideration. PVC-coated mesh fabric can be manufactured to meet various flame-retardant standards, depending on regional regulations and application needs.

When selecting fabric for factories, warehouses, or public spaces, verifying compliance with relevant fire safety standards helps reduce risk and ensures regulatory acceptance.

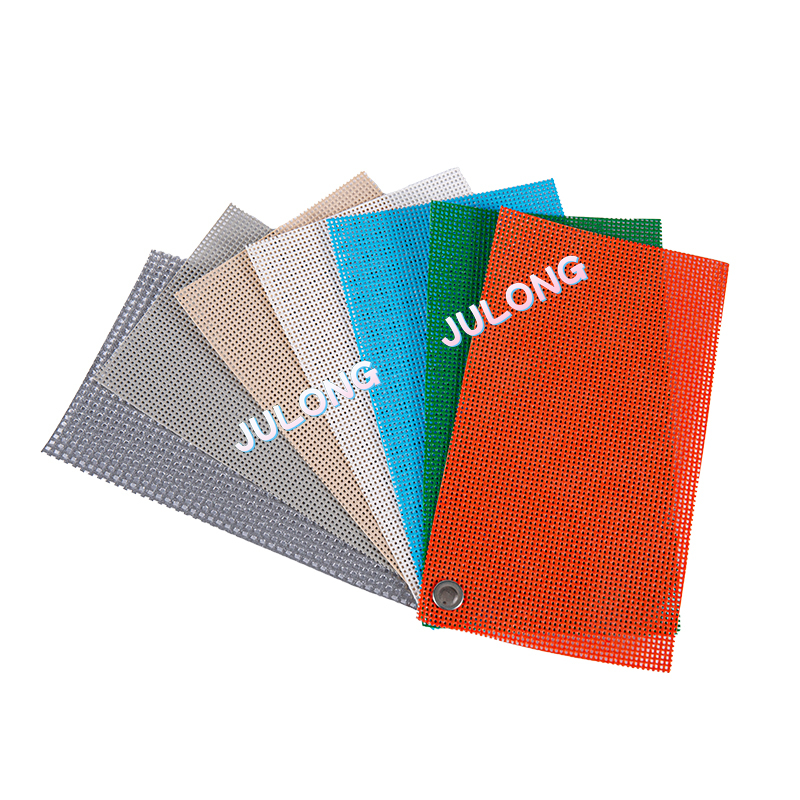

Color, Transparency, and Aesthetic Considerations

While performance is critical, appearance also matters in many outdoor and architectural projects. PVC-coated mesh fabric is available in a wide range of colors, transparency levels, and patterns.

Lighter colors reflect heat and are often preferred for shading structures, while darker colors provide better glare reduction and privacy. Colorfastness is essential to ensure long-term visual consistency under sunlight exposure.

Installation, Fabrication, and Maintenance

Ease of installation can significantly affect project cost and timelines. PVC-coated mesh fabric should be compatible with common fabrication methods such as welding, sewing, or eyelet installation.

From a maintenance perspective, smooth PVC surfaces are easier to clean and resist dirt accumulation. This is particularly beneficial in industrial environments where hygiene or visibility is important.

Balancing Cost and Long-Term Performance

PVC-coated mesh fabric is available in a wide price range, reflecting differences in raw materials, coating quality, and manufacturing standards. Lower-cost options may be suitable for short-term or low-stress applications, but they often have shorter service lives.

For long-term outdoor or industrial projects, investing in higher-quality fabric can reduce replacement frequency, maintenance costs, and operational disruptions.

Practical Checklist for Choosing the Right Fabric

- Confirm operating environment and exposure conditions

- Select appropriate mesh density and yarn strength

- Verify PVC coating thickness and UV resistance

- Check compliance with safety or fire standards

- Balance upfront cost with expected service life

Conclusion: Making an Informed Fabric Selection

Choosing the right PVC-coated mesh fabric for outdoor and industrial projects requires a careful evaluation of technical performance, environmental resistance, and application demands. By understanding how mesh structure, PVC coating quality, and functional requirements interact, project planners and buyers can select a fabric that delivers reliable performance, safety, and long-term value in real-world conditions.

English

English عربى

عربى