PVC-coated fabric is a versatile material that is widely used in the manufacturing of a variety of products. It is made from a layer of PVC to a base fabric of polyester. The resulting material has exceptional strength, durability, and resistance to water, chemicals, and UV radiation. PVC-coated fabric is used in a wide range of applications, including oil isolation fences, air ducts, inflatable tents, and so on. This material can be produced in a variety of colors and patterns, making it highly customizable for different uses. Overall, PVC-coated fabric is a reliable and cost-effective material that is widely sought after in various industries.

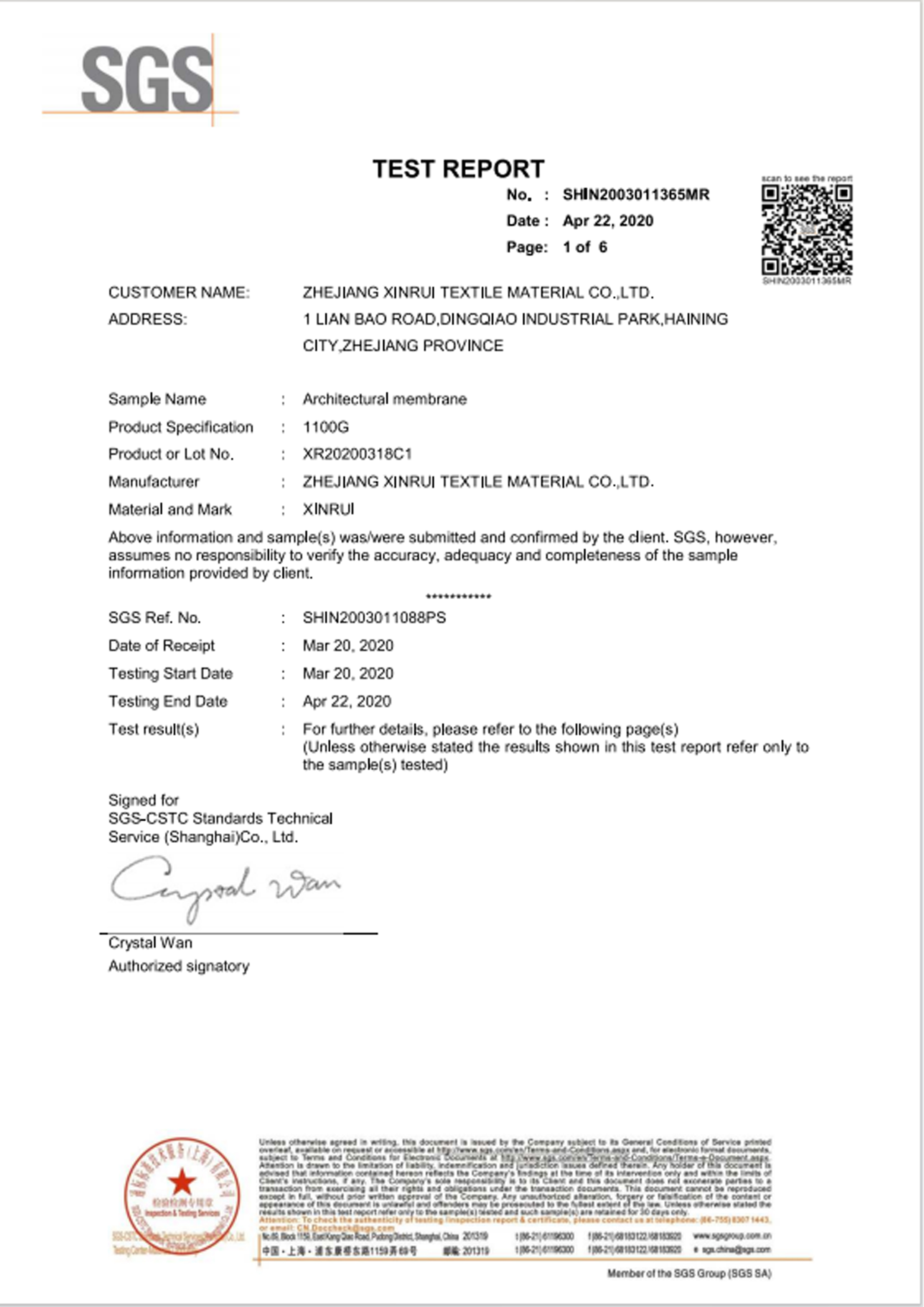

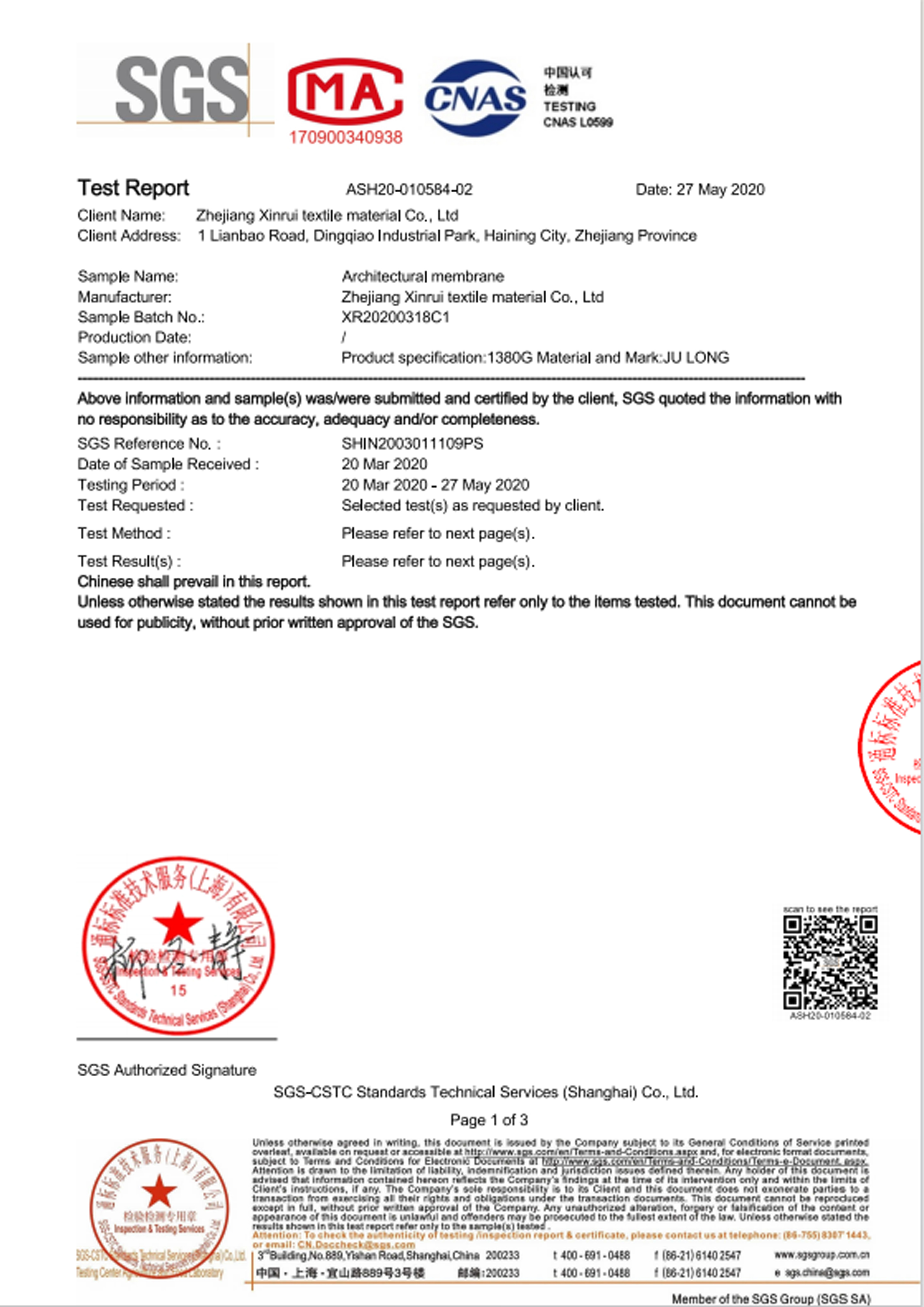

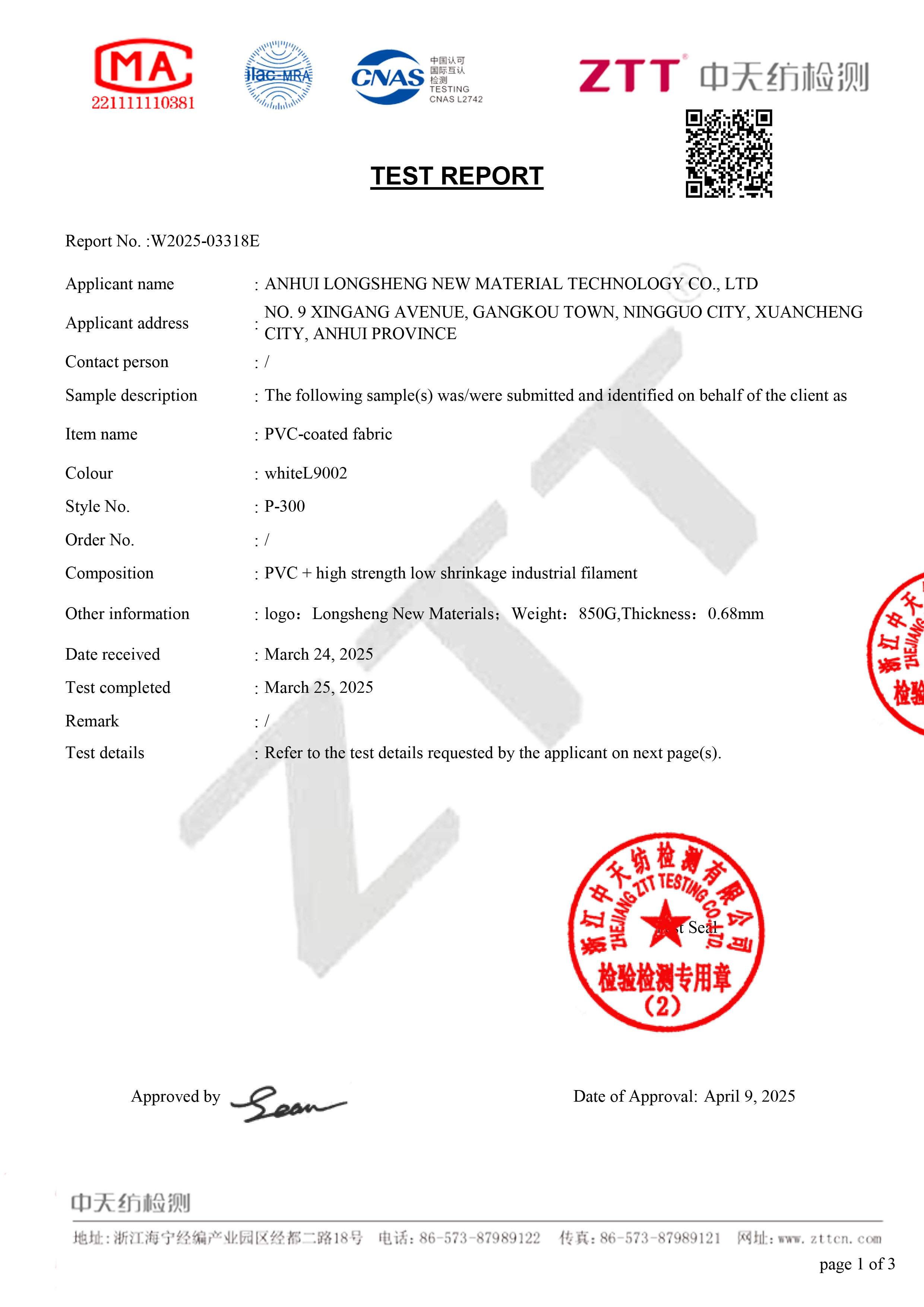

Anhui Longsheng New Materials Technology Co., Ltd. and Zhejiang Xinrui Textile Materials Co., Ltd. were established in 2010. The company specializes in the production of PVC coated fabric, PVC mesh fabric, TPU mesh fabric, mesh fabric and architectural film. The company is located in Qianjiang Industrial Park, Haining City. Since its establishment, it has been committed to the research, development, production and sales of high-quality architectural films or coated fabrics. As PVC Coated Fabric Manufacturers and PVC Coated Polyester Fabric Factory in China, The company has developed and produced products such as ultra-high strength membrane materials, anti-sweating, high light transmittance ultra-transparent membranes, sewage environmental protection membranes, and titanium dioxide membranes. Adopting the advanced technology in the field of European membrane materials, our products are sold well both at home and abroad and have received unanimous praise from customers. Our company's membrane products have been widely applied in large public facilities, such as park landscape buildings, carports, inflatable membrane structures, large sports venues, airport facilities and other construction fields. We supply Wholesale PVC Coated Polyester Fabric. The company has always adhered to the business philosophy of striving for excellence and continuous innovation. Relying on advanced equipment and technology, as well as a forward-looking scientific research spirit, it produces high-quality products, and strives for win-win cooperation with both new and old customers to create a bright future together.

Understanding PVC Coated Fabric Fundamentals PVC coated fabric represents a engineered composite material where polyvinyl chloride (PVC) is applied to a base te...

View MorePVC high speed door fabric represents a critical component in modern industrial and commercial facilities, serving as the primary barrier material for rapid-act...

View MorePVC tarpaulin is a versatile and durable material widely used in industrial, commercial, and outdoor applications. Made from polyvinyl chloride (PVC) coated fab...

View MorePVC mesh pool security barrier fabric is a specialized safety material designed to create a protective perimeter around swimming pools. It is typically made of ...

View MoreUnderstanding the Manufacturing Process of PVC Coated Fabric: From Polyester to Durable Protection

PVC coated fabric is a remarkable material known for its durability, versatility, and strength, making it a go-to choice for various industries. The manufacturing process of PVC coated fabric involves a precise combination of technology, chemistry, and engineering to create a product that not only meets but exceeds the demands of numerous applications. This process begins with a base fabric, typically polyester, which is chosen for its inherent strength and resistance to wear and tear. The polyester fabric serves as the perfect foundation, ensuring that the final product will have a solid structure while maintaining the flexibility necessary for various uses.

The first step in the creation of PVC coated polyester fabric is the preparation of the base fabric. Polyester is carefully selected for its tight weave and high tensile strength, providing a robust foundation for the PVC coating. The polyester fabric is then thoroughly cleaned and pre-treated to ensure it will properly bond with the PVC layer. This cleaning process removes any impurities or residues that could interfere with the coating's adhesion, ensuring a smooth and durable final product. The attention to detail during this stage is crucial, as it lays the groundwork for the material's overall performance and longevity.

Next, the actual PVC coating is applied to the fabric. This is typically done through a process called extrusion or lamination. In extrusion, the PVC material is heated to a molten state and then applied evenly across the fabric. This ensures a strong, uniform coating that will enhance the fabric's resistance to water, UV radiation, and chemicals. Lamination, on the other hand, involves bonding the PVC film to the fabric using heat and pressure. Both methods result in a high-quality PVC coated fabric that can withstand harsh environments while maintaining its flexibility and strength.

The coating itself is composed of a specially formulated PVC compound that enhances the fabric's protective qualities. Additives are mixed into the PVC to improve properties such as UV resistance, flame retardancy, and anti-static qualities. These additives play a key role in enhancing the performance of the PVC coated fabric, making it suitable for use in a wide range of demanding applications. Whether used for outdoor products, industrial covers, or even protective clothing, the quality of the PVC coating determines how well the fabric performs in real-world conditions.

Once the PVC coating has been applied, the fabric undergoes a curing process. This step is essential to ensure that the PVC layer properly bonds with the polyester fabric and reaches its full strength. Curing involves heating the coated fabric to a specific temperature for a set amount of time, allowing the PVC to fully bond and harden. This step ensures that the fabric will remain durable and flexible throughout its lifespan, even when exposed to harsh weather conditions or other environmental factors.

After curing, the PVC coated fabric is thoroughly inspected for quality assurance. This includes checking for uniformity in the coating, any defects or inconsistencies, and ensuring that the fabric meets the required specifications for strength, flexibility, and performance. Manufacturers take great care in this step, as the quality of the PVC coating is directly related to the fabric’s ability to perform under challenging conditions. Any imperfections or flaws are carefully addressed before the material is approved for use in products.

The final step in the manufacturing process involves cutting and finishing the fabric to the desired specifications. This may include rolling, cutting to size, or even applying additional treatments, such as fire retardants or color coatings, depending on the intended application. Whether the fabric is being used for industrial covers, inflatable tents, or oil isolation fences, these finishing touches help ensure that the final product is ready for use in the most demanding environments.

The manufacturing of PVC coated fabric is a highly technical and precise process that results in a durable, flexible, and versatile material that can be customized for a wide range of applications. The combination of high-quality polyester fabric with a protective PVC coating provides outstanding performance in both everyday and extreme conditions. For businesses looking to invest in materials that offer long-lasting protection and reliability, PVC coated fabric offers an excellent solution. With the right manufacturing process in place, the final product delivers not only value but also a trusted material for industries across the globe.